How can businesses realise the results of APM 4.0?

Digital disruption, from the Industrial Internet of Things (IIoT) to Industry 4.0, is impacting all industrial and infrastructure-centric companies and boosting bottom-line metrics across the board.

The extent of its impact depends on a number of factors, including technology, people and access to trusted data. However, another aspect of Industry 4.0 is becoming increasingly central to success: Asset Performance Management (APM) 4.0. Unlocking its potential requires a clear understanding of the five foundational building blocks required to realise its results.

- Prescriptive Analytics: Any successful APM 4.0 programme needs to include predictive and prescriptive analytics. Predictive Analytics provide early warning notifications and diagnosis of equipment issues days, weeks or months before failure. While the benefits of prescriptive analytics span everything from prescribing maintenance activities to postpone or prevent failures, to prescribing operational changes to alter how equipment performs. All of this is possible due to the reduced cost of sensors and network connectivity.

- Smart Connected Assets: The ability to connect physical systems is vital because the ideal outcome for maintenance is smart connected assets. Fully digitised assets lay the groundwork for APM 4.0 by providing a key data source for real-time, historical and predictive analytics. As analytic and automation capabilities evolve, Smart Connected Assets will pave the way for a future of autonomous assets, each operating optimally, independently and continuously improving.

- IIoT Platform: For APM 4.0 to work properly, IIoT platforms are essential to handle the many connections to assets and communication protocols. The key value of an IIoT architecture is the context it provides data. By aggregating data streams into a single source of truth, it's possible to analyse and understand data and make actionable decisions.

- Industry Best Practices: Maintenance professionals must also follow industry best practices to remain at the top of the adoption curve. One of the most prolific asset management standards is ISO 55000; it offers a proven framework for implementing a digital asset management strategy, while remaining flexible enough to meet each organization's unique needs. Companies ensure any investment lives up to its potential by partnering with industry experts to implement their APM 4.0 programmes.

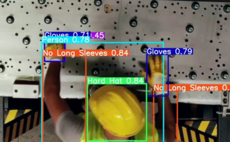

- Killer Mashup Apps: APM 4.0 utilises the sensing, prescriptive analytics and autonomy of smart connected assets and services, and it leverages the connectivity, cloud and predictive capabilities of IIoT platforms - it's a mash-up concept. No surprise then that it requires best-in-class mash-up applications that take content from more than one source, such as video, documents, schedules and voice recordings, to create a single view of information that organisations can understand, deploy and share more easily than before.

The five essential elements of APM 4.0 lay the right foundation to succeed with Industry 4.0. This combination is providing real benefits to companies today. Our clients have seen improvements ranging from a 25 per cent reduction in unplanned downtime, to a 20 per cent increase in asset availability, and up to 30 per cent improvements in asset utilisation.

For more information on AVEVA and its APM 4.0 expertise, please click here.

Kim Custeau is global asset performance management lead at AVEVA. She develops and leads the strategy for industrial Asset Performance Management solutions that help AVEVA customers improve asset reliability and performance to maximise return on capital investments and increase profitability. Kim Custeau has 30+ years of experience in industrial asset management software and services. Prior to AVEVA, she was responsible for the strategic direction, commercialisation and development of Schneider Electric Software's Asset Performance software portfolio globally.

AVEVA Group plc provides innovative industrial software to transform complex industries such as Oil & Gas, Construction, Engineering, Marine and Utilities. AVEVA's software solutions and platform enable the design and management of complex industrial assets like power plants, chemical plants, water treatment facilities and food and beverage manufacturers - deploying IIoT, Big Data and Artificial Intelligence to digitally transform industries.

This is a sponsored article.