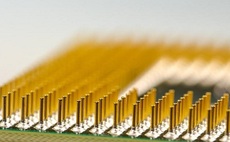

Cambridge scientists grow carbon nanotubes at low temperatures in bid for energy savings

Scientists at Cambridge University have developed a process to make low-energy, high-speed microprocessors that could drastically cut business IT energy bills. The scientists have been working ...

To continue reading this article...

Join Computing

- Unlimited access to real-time news, analysis and opinion from the technology industry

- Receive important and breaking news in our daily newsletter

- Be the first to hear about our events and awards programmes

- Join live member only interviews with IT leaders at the ‘IT Lounge’; your chance to ask your burning tech questions and have them answered

- Access to the Computing Delta hub providing market intelligence and research

- Receive our members-only newsletter with exclusive opinion pieces from senior IT Leaders